By-Pass Valves and Strainers

Industrial Sliding Vane Pumps for LPG

We offer several industrial sliding vane pumps for a wide range of vapor pressures, differential pressures, and viscosities. All industrial pumps are equipped with an adjustable internal relief valve and feature self-adjusting sliding vanes and vane drivers to improve pumping efficiency. And, maintenance is simple. Removing the pump cover gives full access to the rotor, cam, sideplates, seals, and bearings. Drive options include gear reducer, V-belt, and hydraulic.

Suitable liquids include but are not limited to liquefied gases such as LPG, ammonia, and carbon dioxide.

Specifications

|

Flow Rate |

up to 400 gpm (1,514 l/min) |

|

Working pressure: |

up to 28 bar |

|

Differential pressure: |

up to 8.5 bar |

|

Temperature range: |

-30°C to 107°C |

Materials

- Pump casing and heads: Ductile iron

- Cam and side plates: Gray iron

- Rotor and flanges: Ductile iron

- Seal seat: Silicon carbide

- O-rings: Buna-N, PTFE, Viton

Liquids

- Aviation fuels

- Fuel oils

- Liquefied gases (LPG), Ammonia (NH3), Carbon-Dioxide (CO2)

- Lube oils

- Solvents

- And many more

Applications

- Terminal

- Bulk plant

- Mobile (trailers & portable skid units)

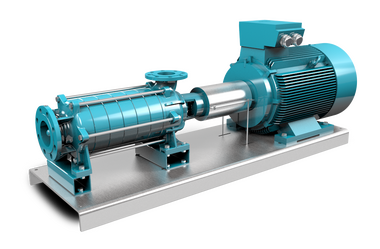

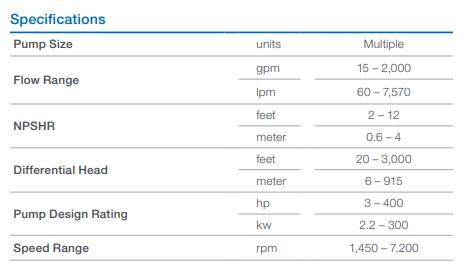

Multi-Stage Pumps for LPG, CO2, LNG

Liquefied gas pumps are required for unloading, refuelling, transferring and filling processes. The requirements for a liquefied gas pump are high: high pressure differences, handling of gas contents, low NPSH (Net Positive Suction Head) values, low-pulsation supply, low noise emission and ATEX conformity. Users of liquefied gas pumps expect safe supply of liquefied gas mixtures, mastering outgassing and fluctuations of the vapour pressure and high pump efficiencies. The efficiency grade of the liquefied gas pump leads to a low energy consumption, smaller drive units and relatively compact pumps.

Liquefied gas pumps are used at different positions within the transport process. Applications are found within tank plants, tank trucks, refrigerating installations, in the beverage industry and in the process technology as well as in ship building. The pumps ensure a safe distribution of liquefied gas along the entire process from production to the end consumer. Liquefied gas pumps are especially used to supply LPG gases (liquefied petroleum gas) such as butane, propane and their derivatives.

Variants of Liquefied Gas Pumps :

Liquefied gas pumps are often considered as LPG pumps, LNG pumps, CO2 pumps. Through a modular design, the pumps are available in a variety of construction styles and materials such as spheroidal graphite iron or stainless steel as well as with different shaft seal systems and drive solutions (explosion-protected motors or also hydraulic drive).

As required, we deliver customer-specific configurations. Of course, we can also provide certificates of all authorized classification societies and necessary test reports.

Advantages

Liquefied gas pumps stand out due to their efficiency, economy and reliability. Moreover, we would like to emphasize the following product advantages and technical characteristics:

- High efficiencies

- Axial thrust-free, open or load-relieved, closed impellers

- Compensation of radial forces due to diffuser elements in the ring housing

- Low NPSH values

- Possibility to convey gas-loaded liquids

- Large operating range

- Suction and flooded supply possible

- High nominal pressures

- Low-pulsation transport of media

- Optional sensor-based operation monitoring

- Low noise emissions

- ATEX-compliant design available

- Explosion-protected motors to customer specifications

- Alternative drive forms available

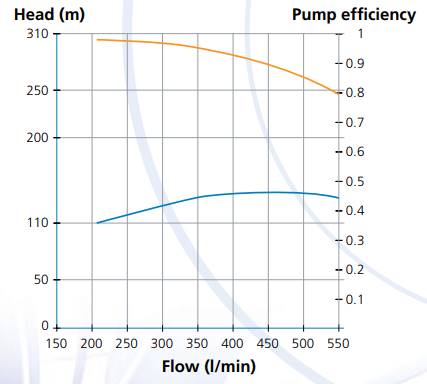

Technical data

- Flow rate: max. 170 m³/h

- Head: max. 300 m

- Permissible operating pressure: up to 40 bar

- Temperature: -50 °C up to +110 °C

- Viscosity: up to 200 mm²/s

POSITIVE DISPLACEMENT PUMPS

CARBON DIOXIDE

ANHYDROUS AMMONIA

REFRIGERANTS

PROPANE

BUTANE

HYDROCARBONS

OIL

LIQUIDS UP TO 20,000 cP, 2-250 GPM

CARBON DIOXIDE

Temp Range: -40°F to + 15°F (-40°C to + -9°C)

Maximum Allowable Working Pressure: 500 psi (34 bar)

Maximum Differential Pressure: 50 psi (4 bar)

ANHYDROUS AMMONIA

Temp Range: -25°F TO +100°F (-32°C to +38°C)

Maximum Allowable Working Pressure: 400 psi (28 bar)

Maximum Differential Pressure: 75 psi (5 bar)

FREONS

Temp Range: -40°F TO +150°F (-40°C to 65°C)

Maximum Allowable Working Pressure: 400 psi (28 bar)

Maximum Differential Pressure: 125 psi (9 bar)

FOR ALL OTHER LIQUIDS*

Temp Range: -80°F to +400°F (-80°C to +205°C)

Inlet Pressure: 4 psiA to 400 psi (0.28 to 28 bar)

Differential Pressure: For liquids under 1 cP viscosity, general maximum differential pressure range between 50-125 psi (4-9 bar). For liquids greater than 1 cP, maximum differential pressure (intermittent duty) up to 300 psi (21 bar).

Capacity: 2 to 250 GPM (7 LPM – 945 LPM)

*General limitations, specifications will differ based on liquid service/viscosity; contact our engineering department for further details

** All pumps are built for their intended liquid service and cannot be interchanged due to differences in materials of construction. Never use a pump for a liquid service other than specified. Mainline Pump Design

•Each secondary housing increases the flow capacity by 50 GPM (190 liters/min)

•Each secondary housing contains 1 drive gear, 2 idler gears

•The mechanical shaft seal assembly is exactly the same, except the length of the drive shaft is increased for each higher capacity pump model

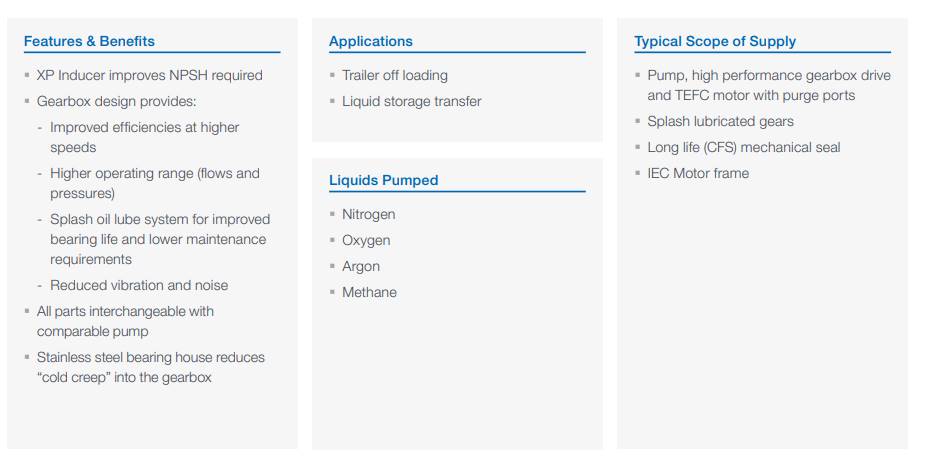

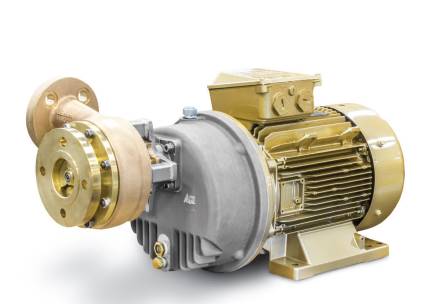

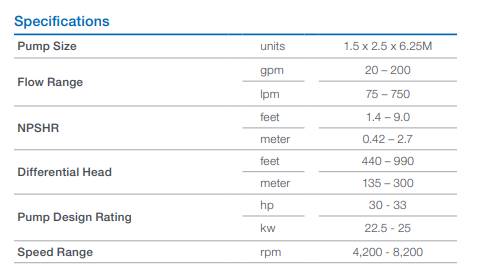

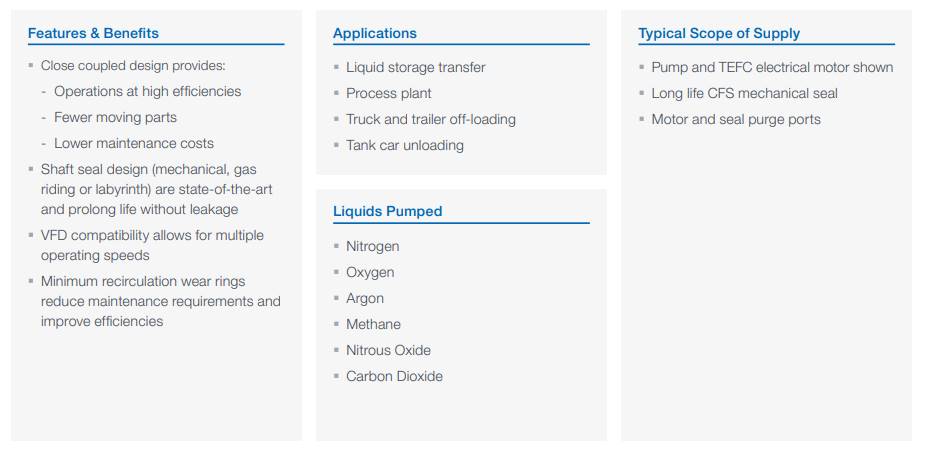

LNG-LIN-LOX-LAR Cryogenic Gas-Liquid Pump

Horizontal direct coupled Cryogenic Pumps with a flow capacity up to 130 m3/h.

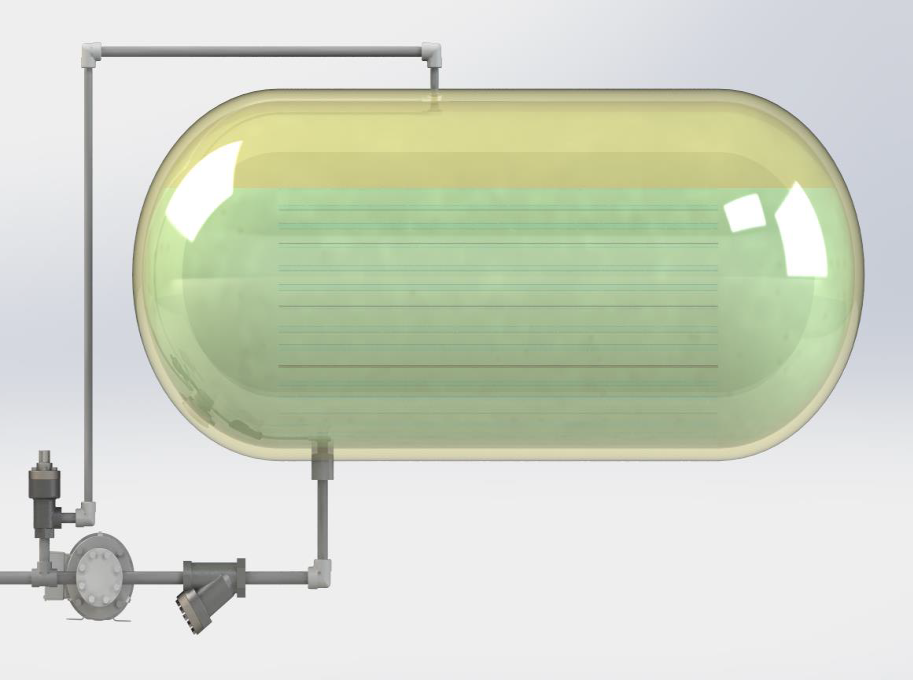

By-Pass Valves

By-Pass valves provide exceptionally close pressure control, even under widely varying bypass flow conditions. Valve maintains a virtually constant pressure of 100 psi (6.89 bar) even as the volume being bypassed rises from 10 gpm to 100 gpm (38-378 L/min).

By-Pass valves provide primary pressure control and are designed to maximize the dispensed flow rate of the overall system. When downstream connections restrict the flow of product less than what is displaced by the pump, the remaining liquid flow is safely returned to the supply tank through the bypass valve connection which avoids damage to the pump. The valve design also maximizes dispensed flow rate by having a narrow pressure band between initial cracking pressure and full pump flow when the delivery line is closed. By-Pass Valves are available in 0.75, 1, 1.25, 1.5, & 2 inch sizes.

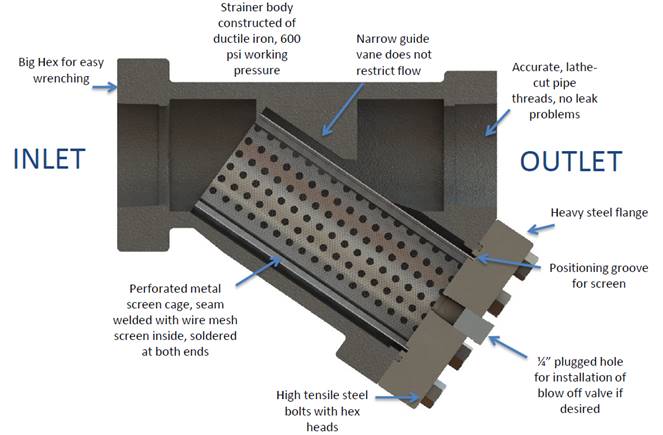

Strainers

•Only strainer designed specifically for liquefied gases

•Oversized design allows for minimal pressure drop

•Removable screen provides ease of maintenance

•Ductile iron construction

•600 psi (40 bar) working pressure

•¾" to 3" and combination sizes available