Gasket

Gaskets materials are found wherever fluids or gases have to be safely contained in pipelines and vessels.

Our gaskets ensure reliable and safe operation – without leakages and subsequent harm or material damage.

Gaskets are employed wherever safe sealing of either conventional or special industrial media, either in the form of liquids or gases, is required.

They are typically employed to ensure exceptionally low leak rates and are also the optimal solution in cases where operators have to work with low bolt loads and relatively low or high temperatures.

Our gaskets increases stability, allowing for easy handling, even when confronted with challenging fitting conditions.

Our gaskets can be used in combination with all types of flange materials, ranging from plastic to steel, and are provided in a wide range of shapes and dimensions.. Amongst others, the product offering includes the EN 1514-1 as well as several sizes of the ANSI standard.

Our gasgetscoffers numerous major advantages, including easy handling, ruggedness and superior sealing capabilities.

Gasket Types:

Compressed Non-Asbestos gaskets

Compression packings

Graphite gaskets

Insulation Sets

Metallic gaskets

PTFE gaskets

SEALEX

COMPRESSED NON-ASBESTOS GASKETS

This type of gaskets, durability of compressed non-asbestos fibre sealing materials. This type gaskets provides excellent resistances (e.g. temperature, mechanical or chemical resistance) in the areas required by the corresponding target industry. Furthermore, this gasket is easy to cut, handle and fit.

COMPRESSED NON-ASBESTOS GASKETS

This type of gaskets, durability of compressed non-asbestos fibre sealing materials. This type gaskets provides excellent resistances (e.g. temperature, mechanical or chemical resistance) in the areas required by the corresponding target industry. Furthermore, this gasket is easy to cut, handle and fit.

COMPRESSION PACKINGS

Compression packings are used to provide an effective sealing function in valves, rotary and reciprocating pump applications.

This products offering ranges from economical traditional packings to high specification PTFE grades, which utilize state of the art technology to produce a product capable of coping with the highest demands of a modern fluid handling system.

- Provides effective sealing in valves as well as rotary and reciprocating pump applications

- Available in a wide range of combinations to suit a wide range of service applications

- Utilization of the most modern production techniques and highest-quality raw materials

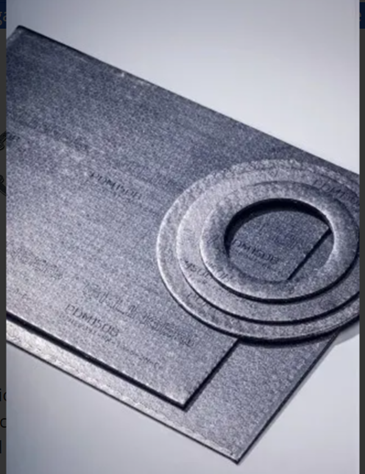

GRAPHITE GASKETS

Graphite-based gaskets are suitable for temperatures between -200 °C and up to 550 °C, and offer resistance against a wide range of chemical products. Equipped with a non-stick finish developed specifically for this purpose, graphite-based gasket materials are easy to remove from the flange, even after exposure to high temperatures. This type of gaskets are using for Cryogenic tank aplication and cryogenic piping. Also this type of gaskets are using fore fire safe aplications.

INSULATION SETS

Insulation sets are primarily used in petrochemical applications to electrically isolate two mating flanges. This reduces the likelihood of creating a galvanic cell which would result in corrosion of the flanges and pipework. Insulation sets are also employed to prevent the flow of electrostatic charges and to reduce sparking in hazardous environments.

Each flange insulation set comprises one insulating gasket, one insulation sleeve as well as insulating washers for each bolt. These sets are individually packed and clearly labeled with the flange rating, size, type and material combination.

METALLIC GASKETS

These gaskets, along with the older style jacketed gaskets are widely used in petrochemical applications. Metallic gaskets often utilize a soft sealing medium such as graphite in conjunction with the metal to create a high-strength, high-integrity gasket. This results in joints with very high leak-tightness.

Metallic gaskets in a wide range of alloys to cover even the most chemically aggressive applications.

Typical Types

Spiral wound gaskets

Kammprofile gaskets

Corrugated gaskets

Ring type Joints

Spiral wound gaskets: Ideal for use in applications where thermal cycling can be a problem

Kammprofile gaskets: combine the benefits of a soft material with the advantage of high integrity sealing of a metal gasket

Corrugated gaskets: particularly suitable for applications involving narrow flanges

Ring type joints: mainly used in offshore applications and certain styles can be adapted for subsea installation.

PTFE GASKETS

Our soft sealing material based on PTFE guarantees maximum chemical resistance and is designed to satisfy most gasket applications. The products of superior chemical product range are tailored to provide the features required by the respective industries. Among others, this includes sealing even at low surface pressures, high resistance against strong acids or strong alkaline solutions, as well as good properties at medium and low temperatures.

This type gaskets especially can be use on LPG, NH3, LCO2, Cryogenic tanks and piping applications.

Using Temperature are Min -200°C, Max + 260°C.

EPTFE SEALING TAPE

The high adaptability, extreme chemical resistance and a wide temperature range of -196 °C to +260 °C make this "seal off the roll" an

Available in 8 different width / thickness ratios

Easy installation with adhesive (also FDA)

Excellent problem-solver.

When you let us know Media type, pressure, type of flange FirstEnergy will be select best option for you.